Introduction

Road construction is a complex task. That’s why every BOMAG paver is systematically designed for efficiency – regardless of the class and whether it is a wheel or chain version. This applies as much to the lower fuel consumption as to fast operational readiness and excellent pre-compaction. Developed and optimised by engineers, who can draw upon half a century of experience, particularly in respect of efficient road construction. Every machine leaves the factory with the highest possible level of reliability. Another reason why selecting BOMAG ensures an investment that pays off for a long time.

Product Features

- BOMAG TELEMATIC – Retrieve location and operating data at any time and manage your fleet more efficiently. Automatic reports provide fuel transparency on fuel consumption, idle times and the potential for fleet optimisation. BOMAG TELEMATIC also includes real time monitoring of pending maintenance and service history.

- Quick change milling drum standard

- Maximum milling performance for an average milling depth at average speed

- Vibration insulation including all operating controls for continuous, stressfree operation.

- Less wear with BOMAG miling drums and variable cutting speed

- Optimised gearhousing

- Optimal ground clearance for milling close to the kerb

- Optimum milling profile for a shallow milling depth at high speed

- Grouped service points

- Maximum productivity, height adjustable, broad swivel range, plus variable belt speed for greater flexibility.

- Maximum milling performance for deep milling at low speed

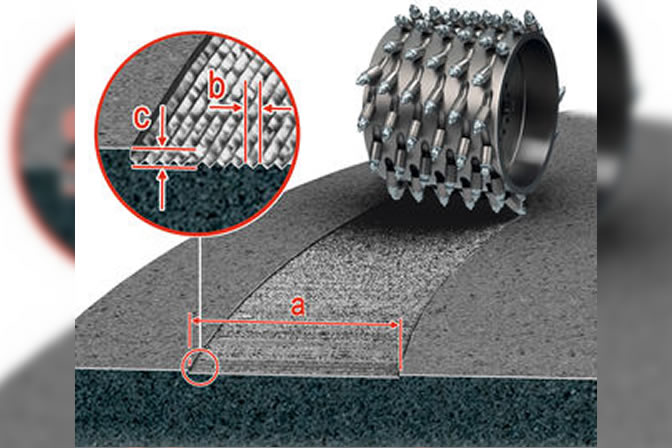

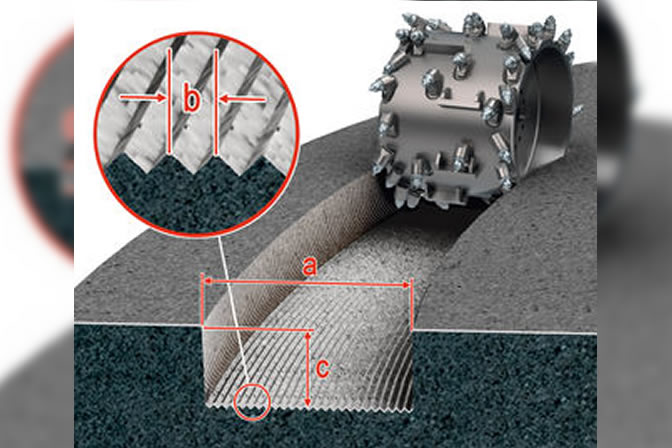

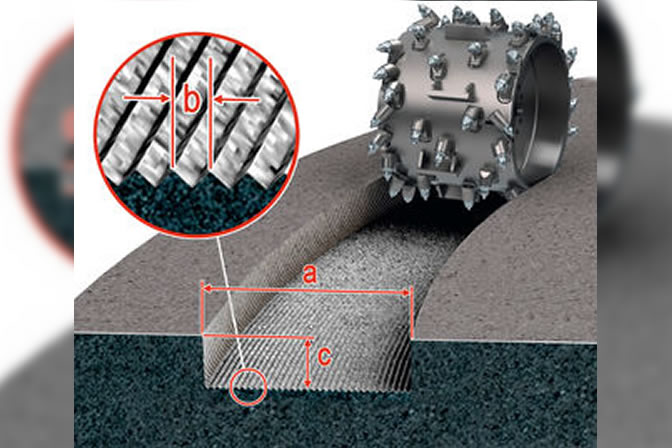

- A planer must mill accurately. BOMAG milling drums feature innovative geometry. The tools are optimally arranged to ensure uniform, low vibration cutting. Due to the shell thickness, the milling drum acts like a flywheel transferring far fewer vibrations to the machine than a conventional drum. This increases planer durability.

- Air intake from above.

Optional Features

- Basic machine

- 4-Wheel-version

- Weather protection roof

- Splitted Scraper

- Port for hydraulik breaker

- Road lights

- Additional working-light, plug in

- Additional working-light, magnet base

- Special colour

- Biodegradable hydraulic oil

- Milling technology

- Milling-Drum 600 LA15

- POWER DRUM 500 LA20

- Fine Milling-Drum 600 LA6

- Milling drum 500 LA15

- POWER DRUM 600 LA20

- Fine Milling-Drum 500 LA6

- Milling drum 400 LA14

- Milling drum 300 LA14

- Loading-system

- Conveyor, long

- Conveyor, long, hyd. foldable

- Conveyor, short

- Automatic Levelling systems

- Levelling Basic, levelling-display, wire-rope sensor, controller (single grade)

- Levelling Advanced 1, additional wire-rope sensor (dual grade)

- Levelling Advanced 2, slope sensor

- Others

- Hydraulic breaker

- Transport trailer

Product Specifications

- Milling technology

- Milling Drum LA15

- 3 Milling-Drum-speeds

- Proportional adjustable water injection

- Automatic water-saving device

- Wear-free, digital Milling-depth-display

- Proportional Milling-depth-adjustment

- Two proportional speeds for Milling-depthadjustment

- Hydraulically operated side-plates

- Hydraulically operated front mouldboard

- Rear mouldboard with adjustable pre-load-pressure

- Right side-plate for fast Drum-exchange

- Automatic load-control

- Automatic distribution of traction

- Drive Systems

- 3-Wheel drive

Right rear wheel foldable from operator place

- Variable transport speed

- Variable operating speed

- Mechanical Drum drive

- Operation comfort

- Fully vibration-isolated operator-platform

- Comfort-workstation for sitting operation

- Seat heating

- Ergonomic adjustable operator seat, 45° to slew

- Ergonomic adjustable steering wheel / column

- Height- adjustable arm-rest with integrated ergonomic operation panel

- Self-explanatory, well-arranged dashboard

- Large storage at ground level

- Service- and maintenance-points ergonomic concentrated

- Safety & environmental protection

- Whisper-package for noise elimination

- Liquid cooled engine following latest emission rules

- Back-up-alarm

- Two driving lights

- variable working-lights

- Rotary-beacon

- CE-conform safety-package with emergency-stop-switches

- Mirror

Vandalism protection

Our Technology

Fine Milling Drum

Power Milling Drum

Standard Milling Drum

Telematic

Product Catalogue

Download a copy of the Cold Planners product catalogue.